Researchers in the U.S. Army Combat Capabilities Development Command's Army Research Laboratory (ARL) are working to develop a drone with the ability to morph while in flight to better fit its mission — for example, shortening and lengthening the wing for efficiency and speed. To begin their work, they turned to the expertise of researchers at Texas A&M University for assistance with the complex analysis and design stage.

A team led by Dr. Darren Hartl, assistant professor in the Department of Aerospace Engineering, tackled part of this first step by developing a novel fluid-structure interaction algorithm. This vital tool will provide ARL researchers with a streamlined means to analyze the interaction between fluid and air flows and flexible or adaptable solid structures in their pursuit of a transforming drone.

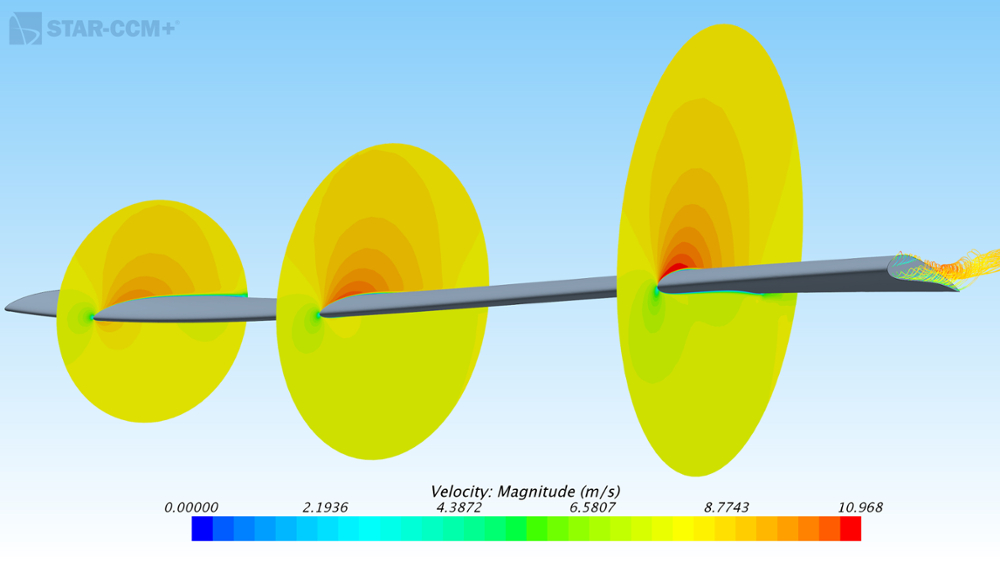

“In aerospace, a really common problem that we have to consider is the interaction between fluid flows and the solid structure that your vehicle is comprised of,” said Hartl. “That analyzing of how the fluid pushes and deforms the structure and how the changing shape of the structure changes fluid flow in a simultaneous way is what is known as fluid structure interaction.”

To elaborate, an airplane, for example, is designed largely based on aerodynamics and should stay stiff and not change shape mid-flight. However, if the wings were allowed to lengthen on longer, international flights, the shape change would alter how the air flows around the original design and how it interacts with the actual physical structure of the plane.

“Fluid-structure interaction in morphing vehicles is much more complicated because motion is intentional," Hartl added. "So that's why we leaned into this problem; we needed a better way to solve fluid-structure interaction.”

Traditionally, fluid-structure interaction is analyzed by running individual fluid and structural codes one at a time, updating the pressure one increment at a time to see how it affects the structure and then updating the structural shape to see how it affects the pressure. This impacts the design process because if any aspect of the design is changed, the expensive fluid-structure interaction scheme has to be redone. This could take days of computation, going back and forth to find the sweet spot for design.

To fix this, Hartl and his team developed an algorithm that substantially cuts down the computational cost by simultaneously running analyses for various pressures and structure shapes, and then using mathematical tools to stitch together two matching solutions.

“I know that, up until this point, we’ve basically been unable to do serious design studies on morphing aircrafts because of this computational expense problem,” said Hartl. “Frankly, this is one reason why there's not a lot of morphing airplane solutions. The only way to have done this in the past was to design, build and test. And one primary problem with structures that can move is that wrong answers quickly lead to catastrophic failures.”

The research team is comprised of collaborators from the U.S. Army Combat Capabilities Development Command's ARL and Texas A&M. Recently, they published their work in “Uncoupled Method for Massively Parallelizable 3D Fluid-Structure Interaction Analysis and Design.”

Bush Combat Development Complex

Hartl especially values this collaboration because it illustrates what is possible by having the Army Futures Command and ARL integrated with Texas A&M. “This algorithm and idea are only a couple years old, and the team was able to harvest it and use it because they were here," Hartl said. "They were the first ones to hear and see about this new way of solving a problem and immediately began applying it to their work.”

The Texas A&M University System’s George H. W. Bush Combat Development Complex (BCDC), under construction at the RELLIS Campus, is the result of a partnership with the Army Futures Command. The BCDC will bring together academic researchers, the military and the private sector for collaboration, demonstrations and high-tech testing of various national security initiatives.