The Texas A&M Engineering Experiment Station (TEES) was established in 1914 and incorporated within The Texas A&M University System in 1948.

TEES boasts a proud history of:

- Serving as a catalyst for collaborations that produce quality research that addresses the needs of our evolving society.

- Transferring emerging technology to the private industry;

- Supporting the state’s workforce development through continuing and professional education.

1910s

Establishment of TEES

TEES was established on Aug. 25, 1914, by the Agricultural and Mechanical College of Texas’ board of directors to conduct engineering research to help build a better society. Its mission was to undertake research that would produce answers to urban difficulties, as well as disseminate information related to such problems, thus enhancing the quality of life in Texas.

Since its inception, TEES has continued to direct its efforts to the utilization of natural resources and the improvement of industrial processes for over 100 years. It is the state's leader in innovation engineering and enables the government and industry partners to deliver advanced technology solutions to key market segments.

TEES is organized for the purpose of affording a service to industries of Texas ... assisting the urban population of the state in solving the technical problems of urban life; investigating engineering and industrial problems of especial importance to Texas and of disseminating information along those lines.

Responding to national need

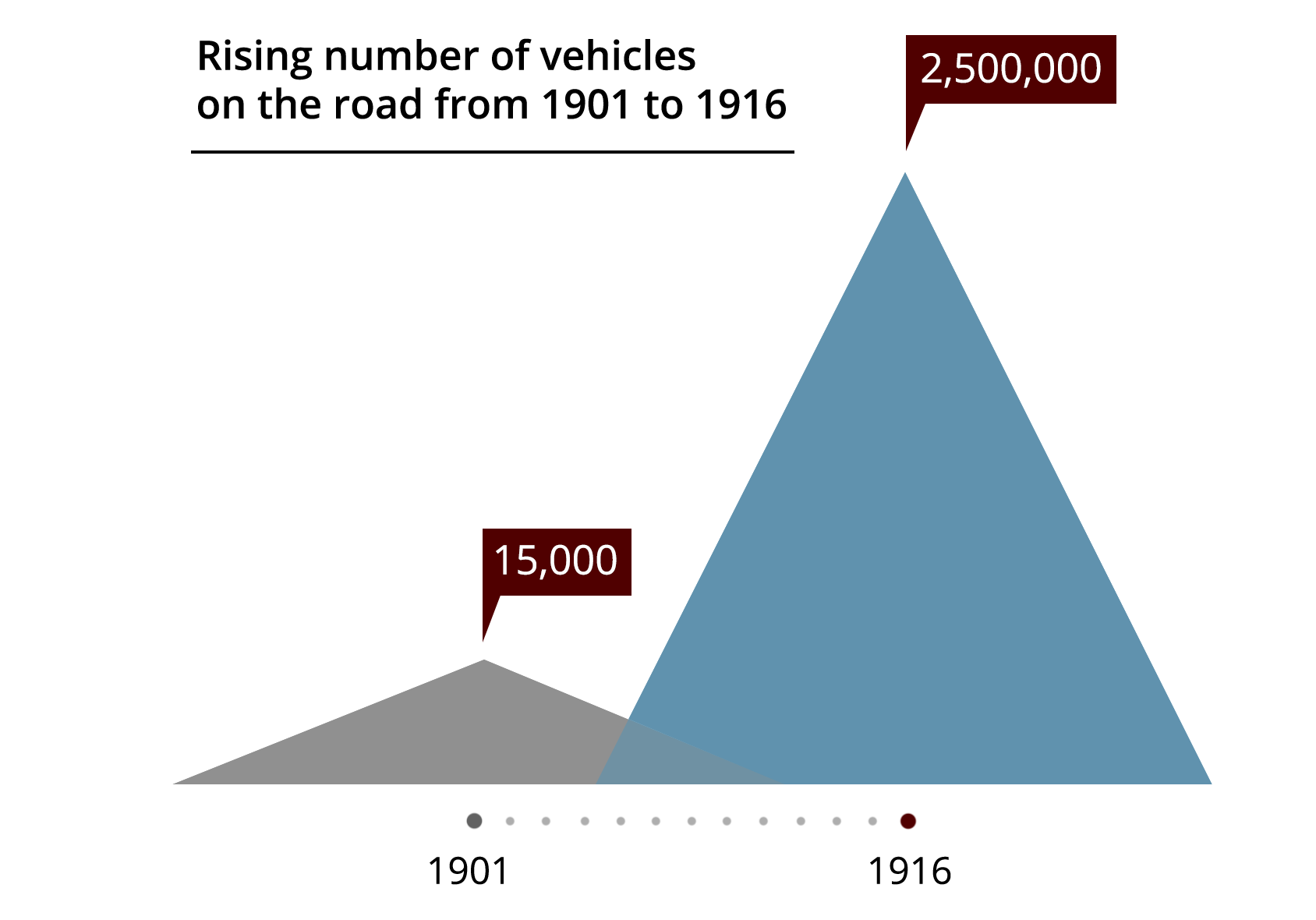

The agency's creation coincided with the automobile boom of the early 1900s when the number of cars increased from 15,000 in 1901 to 3 million in 1916 and only 10% of the nation's 2.6 million miles of road were surfaced.

TEES responded to the cries for better roads by creating a series of printed bulletins on the best ways to build highways, culverts and bridges. These were widely used by the Texas Department of Highways and Public Transportation. These early research efforts eventually spawned the Texas A&M Transportation Institute (TTI).

Leaders in engineering

1920s

Interest in scientific research emerged with the end of World War I in 1919. Americans wanted technology implemented to help them in their everyday lives. The country entered a new industrial revolution with automobiles leading the way. Industries such as rubber, glass, fabrics, petroleum, tourism and agriculture emerged.

First appropriation of state money

Staffed only with volunteers, TEES continued its highway research and investigations into rural electricity needs and urban sewage disposal. It wasn't until 1921 that TEES received state funding, taking in $6,000 for 1921-1922.

Earning research money

F.C. Bolton, TEES director as well as the college’s dean of engineering, set out to earn research money rather than wait for it to be appropriated.

We felt that since we didn’t have the funds to employ men to carry on the work, little could be done. However, we have turned over a new leaf and are not going to wait for more funds, but are going to show results with what we have and then ask for funds to carry on greater work.

Military roots

During World War I, F.C. Bolton led war training activities and education for Army soldiers training at Texas A&M University. Years later, during World War II, Texas A&M once again served a dual purpose as an education institution and a specialized training base for soldiers. This time, Bolton served as campus liaison between college and military personnel.

1930s

Weathering the Great Depression

Not impervious to the effects of the Great Depression, TEES' budget shrank from $15,600 in 1932 to $1,900 in 1933, resulting in wilting research efforts and publications.

However, the Depression years benefited TEES. The legislature gave the Agricultural and Mechanical College access to a permanent university fund that contained revenue earmarked for use by land-grant colleges. This fund allowed the college to spend $3 million on capital improvements between 1929-1937—more than it had spent in the previous 50 years. TEES used the college's construction boom as a focus for research, particularly because TEES director F.E. Giesecke was overseeing these improvements for the college.

New facilities established

- Cotton Fiber Testing Lab (1937) - Began to aid the Rural Electrification Administration (REA) to help bring electricity to rural and farm areas.

- Fan Testing Lab

- Energy Systems Lab (1939)

Finishing strong

Every major capital improvement undertaken by Texas A&M in the 1930s involved TEES. The agency did studies on building foundations, materials, heating and ventilation systems, air conditioning equipment, water supply and sewage treatment facilities.

At the close of the 1930s, TEES was stronger than any time in its history. Its budget increased from $1,900 in 1933 to $40,000 in 1939, and the agency established several significant research thrusts.

1940s

World War II completely altered the picture of engineering college research as the government turned to its institutions of higher education by awarding a great number of defense contracts to university research. Before the war, TEES pursued research of rural electrification, attic fans and sewage treatment, and bulletins on these topics were in high demand. TEES research projects were curtailed until the end of the war in 1945 because a number of researchers served in the war.

Branching out

During the 1940s, TEES branched out into petroleum refining and school architecture. In fact, the success of its school architecture project led to the design of a multimedia package in 1948 that included a 16-millimeter color film entitled Building for Learning. The film circulated nationwide and was in constant demand until 1960, when it was retired due to excessive wear.

Developing the crop duster airplane

In 1949 TEES, along with the Texas A&M AgriLife Extension Service, began developing a crop dusting, spraying, seeding and fertilizing aircraft which later went into production and is still used for crop dusting planes.

With the rising interest in UAV or drone technology, TEES researchers continue to work on perfecting precision agriculture. The Federal Aviation Administration approved a Certificate of Authorization (COA) that grants Texas A&M researchers permission to fly UAS over the 3,200 acre Texas A&M Brazos Bottoms Farm. Located near College Station, Texas, the farm supports an array of projects for agricultural scientists.

Transportation connection

1950s

After watching the Soviet Union launch the first man-made object into orbit, Americans felt a strong need to emphasize math, science and engineering in the public education system. At the same time, money began to flow into research as federal research expenditures doubled and basic scientific research funds tripled.

Introduction of cutting-edge technology

The 1950s were a pivotal time for TEES, and the agency became involved in cutting-edge technology. TEES' first venture into high technology involved computers. TEES acquired an IBM 650 digital computer and an IBM 709 in the late 1950s and created a Data Processing Center which brought the age of computerization to Texas A&M and allowed data processing courses to be offered for the first time.

Establishment of new facilities

- Nuclear Science Institute (1958)

- Texas Transportation Institute (1959)

- TEES Data Processing Center

Nuclear science and engineering

TEES also branched into nuclear science and engineering, constructing an AGN 201M nuclear reactor for training and research into the fields of isotopes and radiation safety. Efforts grew from there to obtain a more sophisticated reactor to address agriculture, industry, veterinary and human medicine.

1960s

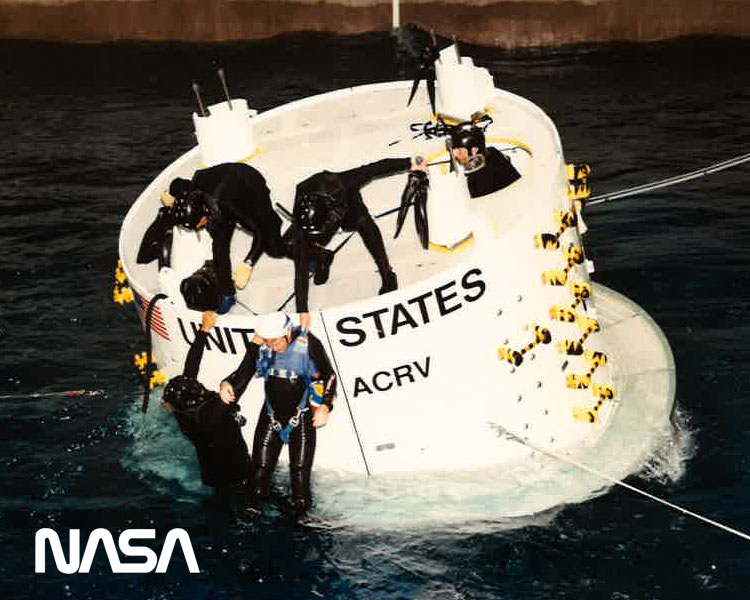

Fueled by the Space Race between the United States and the Soviet Union, TEES expanded its space research to aid the U.S. progress and established the Space Technology Division in 1962. TEES’ research contributed to the technological success of Neil Armstrong and Edwin Aldrin’s walk on the moon in 1969. TEES researchers were among the 300,000 individuals who pledged their expertise and spent millions of hours to ensure this historical success.

Even as NASA’s plans become more ambitious as years pass, the organization is still asking many of the same foundational questions about space that it asked when Apollo 11 landed on the moon: What’s out there? How do we get there? What will we find? TEES researchers continue to strive to produce research and solutions that address those questions.

New labs, centers and divisions established

- Space Technology Division (1962)

- Electric Power & Power Electronics Institute (1964)

- Remote Sensing Center (1968) - established for the development of microwave equipment for information gathering tasks by satellites. This center also did air and water quality monitoring as well as forest fire and oil spill detection.

- Highway Safety Research Center (1968)

- Center for Dredging Studies (1968)

- Coastal Engineering Lab (1968)

- Solid-State Electronics Lab (1969)

Space-grant institution

1970s

The 1970s presented many challenges in the way of pollution, energy shortages, world hunger, fierce economic competiveness and transportation problems.

The decade also saw an increase in bioengineering studies. TEES researchers studied prosthetics, bone grafts and modified vehicles for quadriplegics. In 1973, TEES researchers developed a voice and breath-controlled wheelchair.

Responding to national need with new research labs and centers

- Food Protein Research and Development Center (1971) - established to examine cottonseed, fish, sunflowers, sesame seeds and peanuts as alternative sources of food protein. This allowed U.N. sponsored university grad students to attend Texas A&M and conduct research projects as part of their degree programs.

- Texas Occupational Health and Safety Institute (1971)

- Turbo Machinery Lab (1971) - The creation of the Turbo Machinery Lab improved performance and life of power equipment to help industry save on energy costs.

- Center for Urban Programs (1973)

- Prairie View Engineering Research Center (1979)

Calculating success

In the early years of this decade, computers were still new enough that it wasn't common for individual researchers to have easy access to them. Most computer applications used main-frame computers, "punch card" entry and very limited or nonexistent graphics. Software often had to be written by the user.

However, TEES didn't let that stand in the way of technology development. Researchers working at facilities such as the Turbomachinery Laboratory did most calculations by hand or with slide rules since supporting technologies for turbomachinery applications were still developing at the time.

Highway and urban engineering

1980s

The 1980s were a time of wide-ranging expansion for TEES. In 1989, the 71st Texas Legislature recognized TEES as a statewide research and technology agency. And with a budget of $36 million and the addition of five new divisions and 11 new centers, TEES started expanding its scope to worldwide engineering research problems as well.

First ERC in the southwest

In 1988, Texas A&M University and the University of Texas at Austin partnered to create the NSF Engineering Research Center (ERC) for Offshore Technology. Managed by TEES, this ERC supports the offshore oil and gas industry and conducts basic engineering research and develops systems for the economical and reliable recovery of hydrocarbons at ocean depths of 3,000 feet or more. During this decade, the Offshore Technology Reseacher Center achieved a leadership role in cutting-edge research on critical elements of the deepwater production problem.

Centers created

- Marine Geotechnical Engineering (1980)

- Crisman Institute for Petroleum Research (1984)

- Space Research Center (1985)

- Center for Electrochemical Systems & Hydrogen Research (1985)

- Center for Space Power (1987)

- Center for Studies of Clusters and Microparticles (1987)

- Thomas A. Read Center for Distribution Research (1987)

- Hazardous Waste Research Center (1987)

- Hazardous Reduction and Recovery Center (1988)

- Space Power Institute (1989)

- Offshore Technology Research Center (1989)

New divisions established

- UT Arlington

- UT El Paso

- UT San Antonio

- Texas A&I University

- Lamar University

Regional needs

1990s

During the 1990s, TEES received $11 million for funding programs encouraging women and minorities in engineering, math and science. It also placed more emphasis on multidisciplinary and applied research.

Recognition for applied research

TEES was recognized by the R&D 100 Awards for inventions that demonstrated multidisciplinary capabilities and won other prestigious honors such as the Presidential Green Chemistry Awards Challenge for innovative technologies that help the environment.

Notably, Rayford Anthony and C.V. Phillip, in conjunction with Sandia National Lab and UOP Co., created a material that cleans radioactive waste. B. Don Russell, Carl Brenner, and M. Michael Aucoin invented a digital feed monitor (manufactured by G.E.) that detects broken overhead power lines. And Mark Holtzapple determined a way to turn waste into animal feed, industrial chemicals and fuel.

TEES also established more research centers than during any other decade, decidedly establishing its foundation for continued pursuance of funding and resources for multidisciplinary applied research in the decades to come.

Centers established

- Center for Electronic Materials, Devices and Systems (1990)

- Center for Mechanics and Control (1990)

- Environmental Excellence Center (1991)

- Innovation and Design in Engineering (1992)

- Mechanics of Composites (1992)

- Nanostructure Material and Quantum Device Fabrication (1992)

- Thermodynamics Research Center (1992)

- Sustainable Enterprise Institute (1992)

- Manufacturing Systems (1992)

- Scientific Computation (1992)

- Center for Oil Spill Technology (1992)

- Center for Asphalt and Material Chemistry (1992)

- Polymer Technology Center (1993)

- Infrastructure Engineering (1993)

- Center for Telecommunications Technology Management (1993)

- Texas Center for Applied Technology (1994)

- Mark Kay O'Connor Process Safety Center (1995)

- Center for the Study of Digital Libraries (1995)

- Ergonomics Center (1996)

- Telecommunications and Information Technologies (1997)

- Analog and Mixed Signal Center (1998)

- Spacecraft Technology Center (1998)

- Aerospace Vehicle System Institute (1998)

- Center for Community Support (1999)

2000s

As technology became more sophisticated and readily available, TEES continued to be a leader in engineering innovation, research and training.

Centers and institutions established

- Biomedical Imaging and Sensing Engineering Center (2001)

- Intelligent Bio-Nano Materials & Structures for Aerospace Vehicles Institute (2002)

- Texas Institute for Intelligent Bio-Nano Materials & Structures for Aerospace Vehicles Institute (2002)

- Dynamic Systems & Control (2002)

- Space Engineering Institute (2003)

- Aerospace Design, Safety/Security & Integration Center (2003)

- Center for Large-Scale Scientific Computing (2006)

- Nuclear Security Science & Policy Institute (2006)

- Institute for National Security Education & Research (2007)

2010s

TEES continues to push ahead in research into alternative energy and works collaboratively in all research areas with government agencies, national labs and TEES institutes. It was awarded $22.7 million for bio manufacturing workforce training and began construction on several new facilities, including Texas A&M-RELLIS, the Bush Combat Development Complex, and the Center for Infrastructure Renewal.

Notable milestones

During this decade, TEES celebrated its 100th anniversary in 2014 and renewed its focus on mission-focused applied research. Specific research focus areas included health care, infrastructure, advanced manufacturing, cybersecurity, autonomous vehicles and smart grid reliability.

In 2015, the Frederick E. Giesecke Engineering Research Building, named after a former TEES director, was established to focus on nanofabrication, materials characterization and energy research.

TEES also hosted the inaugural Texas A&M New Ventures Competition to provide seed funding for Texas companies with high-growth potential and innovative product development ideas.

Innovation through manufacturing

Strengths in advanced manufacturing resulted in TEES leading six regional manufacturing innovation centers as key components of the USA manufacturing innovation institutes network. TEES also established the SecureAmerica Institute to facilitate the execution of projects that benefit from collaboration between academia and industry.

Centers and institutions established

- National Center for Therapeutics Manufacturing (2010)

- Wind Energy Center (2010)

- Water Conservation & Technology Center (2012)

- Center for Emergency Informatics (2012)

- Smart Grid Center (2012)

- National Corrosion Center (2013)

- Institute for Engineering Education and Innovation (2013)