In a state as vast as Texas, temperatures can be extreme. From the daunting heat of long summer days to record-breaking cold snaps, the drastic fluctuation has the potential to adversely affect infrastructure.

“It is a combination of materials and landscape,” said Dr. Anand Puppala, interim director for the Center for Infrastructure Renewal (CIR) at the Texas A&M Engineering Experiment Station and professor in the Zachry Department of Civil and Environmental Engineering at Texas A&M University. “Whether it is underground piping providing water and electricity or roadway surfaces for commuters, the environment and changing weather patterns play a significant role in the resiliency of materials traditionally used for infrastructure.”

Research underway at the CIR, located at the Texas A&M-RELLIS campus, encompasses all aspects of infrastructure, from concrete and asphalt to plastics and polymer additives. With a targeted outcome of developing sustainable options, an interdisciplinary network of experts collaborates to form new methodologies, improve longevity and initiate comprehensive test cases.

“Learning how to design materials that can withstand a broad range of change — expansion, contraction of soil or extreme hot and cold temperatures — helps shape our research,” said Puppala. “Access to laboratories with specific testing capabilities like corrosion, controlled temperature pods and more allows us to scale up our testing and expedites our ability to respond to industry and government needs.”

Geotechnical and unbound materials research

In June 2022, residents of Odessa, a city in West Texas, experienced firsthand the detrimental impact of degrading infrastructure when a water main failed, leaving 165,000 homes and businesses without potable water for more than 24 hours. In addition to the material composition of the water lines themselves, the expansion and contraction of the soil plays a role in how long underground utility lines can last.

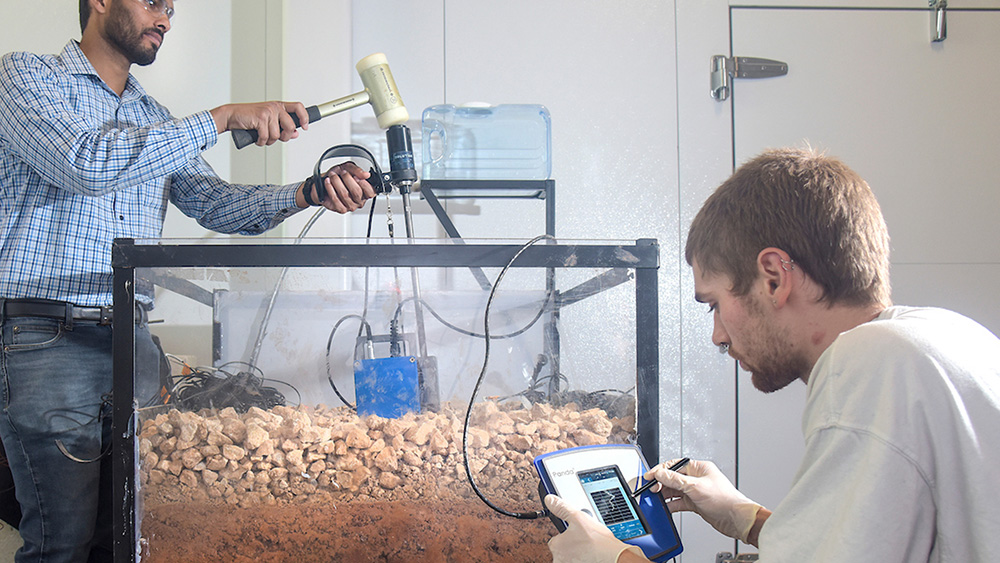

“From the geotechnical perspective, we are exploring how additives may stabilize different soil types and compositions to reduce the stress placed on the lines underground,” said Puppala. “We simulate the real-life fluctuation of soil conditions to see if and how the additives reduce the effects of soil shifting in seasons of drought and flooding.”

Like underground utilities, residential home foundations are susceptible to the adverse effects of soil compound expansion and contraction. Puppala leads an Industry-University Cooperative Research Centers (IUCRC) Program initiated by the National Science Foundation (NSF) in 1973 to strategically integrate industry, academia and government partners. His area of focus is on the use of polymeric composite products to strengthen geo and civil infrastructure.

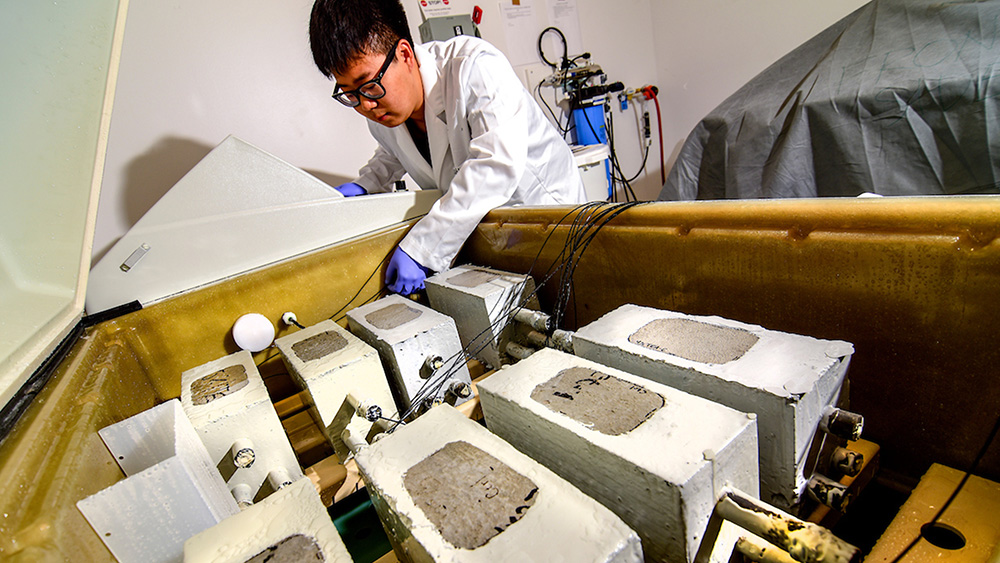

“Foundations shift and are exposed to differing temperatures, both above and below the ground’s surface,” said Puppala. “Through NSF IUCRC-sponsored research, we are scaling up a thermo-block insulation application that helps reduce heat absorbed by structures to help prevent cracking and foundation maintenance needed, or at the very least, prolong the life of the slab before repairs are necessary.”

Advancements like these can bring relief to both new and existing infrastructure through implementation at the design phase or retrofitting as needed.

Manufacturing and materials research

Parallel to the impacts of geotechnical components, identifying the resiliency of material types and their reaction to different elements found within the soil is important. Dr. Homero Castaneda-Lopez leads the National Corrosion and Materials Reliability Lab, a CIR facility that provides small- to full-scale testing for industry, government and academic partners.

“We help identify how different materials — from metal piping and plastic casing to concrete and asphalt — respond in corrosive and extreme environments,” said Castaneda-Lopez. “Bringing together the data of geotechnical impacts and corrosion helps us see how materials and civil engineers can work in tandem to develop more resilient infrastructure materials.”

Health monitoring of the infrastructure is an important aspect of quantifying and characterizing an asset’s reliability. Data from this proactive measure provides insight into the sustainability of current structures and directly influences the environmental impact of the degradation process.

This same interdisciplinary approach applies to testing concrete and asphalt for roadway surfaces and bridges. Research into the use of polymers is underway to see how different additives can preclude bleeding of asphalt pavements and provide pliability in concrete structures — while maintaining their structural integrity — during high temperatures.

A portion of a state highway in East Texas began to ‘melt’ in June 2022 as a result of prolonged and extreme heat. While this was actually the asphalt binder rising to the surface due to high temperatures, it forced lane closures and delayed the traffic flow so crews could address the issue. Considering that the Texas Department of Transportation has 80,444 centerline miles of highways and more than 35,000 bridges to maintain across the state with 540 million vehicle miles traveled annually, there is a vested interest in reducing the need for maintenance through improved materials selection and engineering of materials combinations.

“Identifying materials that can withstand a volatile change in temperatures is a focus of the integrated network of researchers at the CIR,” said Dr. Zachary Grasley, department head and professor of the civil and environmental engineering department at Texas A&M.

Reducing the cost and carbon footprint of infrastructure materials also ties into the sustainability aspect of this infrastructure research. Dr. Petros Sideris, assistant professor in the civil and environmental engineering department, is leading a U.S. Department of Energy Advanced Research Projects Agency-Energy study using hempcrete for residential and commercial construction designs.

“Hempcrete and other materials with a negative or low carbon footprint can lead to designs that combine sustainability and resilience for our structures and infrastructure,” said Sideris. “This could provide a path to addressing the impacts of climate change on our infrastructure.”

With an estimated cost of $2.59 trillion for current U.S. infrastructure needs, the CIR provides a network of researchers and laboratories equipped to meet today’s challenges by adapting for the needs of tomorrow.