Extrusion-based 3D printing/bioprinting is a promising approach to generating patient-specific, tissue-engineered grafts. However, a major challenge in extrusion-based 3D printing and bioprinting is that most currently used materials lack the versatility to be used in a wide range of applications.

New nanotechnology has been developed by a team of researchers from Texas A&M University that leverages colloidal interactions of nanoparticles to print complex geometries that can mimic tissue and organ structure. The team, led by Dr. Akhilesh Gaharwar, associate professor and Presidential Impact Fellow in the Department of Biomedical Engineering, has introduced colloidal solutions of 2D nanosilicates as a platform technology to print complex structures.

2D nanosilicates are disc-shaped inorganic nanoparticles 20 to 50 nanometers in diameter and 1 to 2 nanometers in thickness. These nanosilicates form a “house-of-cards” structure above a certain concentration in water, known as a colloidal solution.

These colloidal solutions have appealing properties when studying the deformation of a material, such as increased viscosity and yield stress as well as shear thinning, where viscosity reduces under strain, and thixotropic behavior, where a material deforms in response to applied forces. The Gaharwar Laboratory leverages the rheological properties of these nanosilicates for extrusion-based 3D printing.

The results of the team’s research were published in the journal Bioprinting. The research was supported by the National Institute of Biomedical Imaging, Bioengineering of the National Institutes of Health and the President's Excellence Fund (X-Grants and T3).

New nanotechnology has been developed by a team of researchers from Texas A&M University that leverages colloidal interactions of nanoparticles to print complex geometries that can mimic tissue and organ structure. The team, led by Dr. Akhilesh Gaharwar, associate professor and Presidential Impact Fellow in the Department of Biomedical Engineering, has introduced colloidal solutions of 2D nanosilicates as a platform technology to print complex structures.

2D nanosilicates are disc-shaped inorganic nanoparticles 20 to 50 nanometers in diameter and 1 to 2 nanometers in thickness. These nanosilicates form a “house-of-cards” structure above a certain concentration in water, known as a colloidal solution.

These colloidal solutions have appealing properties when studying the deformation of a material, such as increased viscosity and yield stress as well as shear thinning, where viscosity reduces under strain, and thixotropic behavior, where a material deforms in response to applied forces. The Gaharwar Laboratory leverages the rheological properties of these nanosilicates for extrusion-based 3D printing.

The results of the team’s research were published in the journal Bioprinting. The research was supported by the National Institute of Biomedical Imaging, Bioengineering of the National Institutes of Health and the President's Excellence Fund (X-Grants and T3).

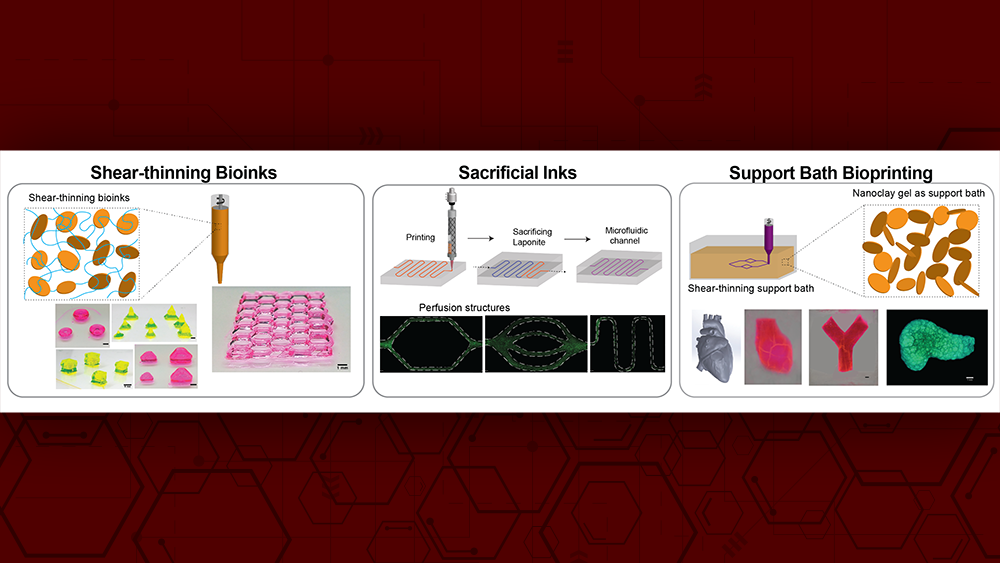

Some major challenges in extrusion-based 3D printing are the inability to print tall and complex structures, as soft materials flow under gravity and cannot form self-supporting structures. To overcome these challenges, researchers used colloidal nanosilicates and demonstrated them as a platform technology for bioprinting using three different approaches.

In the first approach, Satyam Rajput, a biomedical engineering graduate student in the Gaharwar Laboratory and the lead author of the paper, designed a shear-thinning ink composed of nanosilicates and water-soluble polymers such as agarose, alginate, kappa-carrageenan, gelatin, gelatin methacryloyl, polyethylene glycol and N-isopropyl acrylamide. The printable ink formulation showed good shape fidelity.

In the second approach, the team demonstrated the use of nanosilicates as a sacrificial ink, an instrument designed to fail and be removed, to design microfluidic devices for in vitro disease modeling. These perfusable devices can be used for various applications to emulate and study vascular physiology and fluid mechanics, disease models, tissue organization and function, therapeutic tissue engineering, and 3D-cell culture models and screen drugs.

In the third approach, the researchers utilized a colloidal nanosilicate gel as a support bath for 3D printing by nullifying the surface tension and gravitational forces. A range of complex structures such as a bifurcated vessel, femur, meniscus, DNA double helix, heart and trileaflet valve were printed inside the support bath.

“The versatility of nanosilicates could be widely adopted in the fields of additive manufacturing, tissue engineering, drug delivery and medical devices,” Gaharwar said.

Other authors who contributed to this study are biomedical engineering graduate students Kaivalya Deo, Tanmay Mathur, Giriraj Lokhande, and Kanwar Abhay Singh; Dr. Yuxiang Sun, associate professor in the Department of Nutrition; Dr. Daniel Alge, associate professor in biomedical engineering; Dr. Abhishek Jain, assistant professor in biomedical engineering; and Dr. Tapasree Roy Sarkar, assistant professor in the Department of Biology.

In the first approach, Satyam Rajput, a biomedical engineering graduate student in the Gaharwar Laboratory and the lead author of the paper, designed a shear-thinning ink composed of nanosilicates and water-soluble polymers such as agarose, alginate, kappa-carrageenan, gelatin, gelatin methacryloyl, polyethylene glycol and N-isopropyl acrylamide. The printable ink formulation showed good shape fidelity.

In the second approach, the team demonstrated the use of nanosilicates as a sacrificial ink, an instrument designed to fail and be removed, to design microfluidic devices for in vitro disease modeling. These perfusable devices can be used for various applications to emulate and study vascular physiology and fluid mechanics, disease models, tissue organization and function, therapeutic tissue engineering, and 3D-cell culture models and screen drugs.

In the third approach, the researchers utilized a colloidal nanosilicate gel as a support bath for 3D printing by nullifying the surface tension and gravitational forces. A range of complex structures such as a bifurcated vessel, femur, meniscus, DNA double helix, heart and trileaflet valve were printed inside the support bath.

“The versatility of nanosilicates could be widely adopted in the fields of additive manufacturing, tissue engineering, drug delivery and medical devices,” Gaharwar said.

Other authors who contributed to this study are biomedical engineering graduate students Kaivalya Deo, Tanmay Mathur, Giriraj Lokhande, and Kanwar Abhay Singh; Dr. Yuxiang Sun, associate professor in the Department of Nutrition; Dr. Daniel Alge, associate professor in biomedical engineering; Dr. Abhishek Jain, assistant professor in biomedical engineering; and Dr. Tapasree Roy Sarkar, assistant professor in the Department of Biology.