Fiber-reinforced thermoplastics (i.e., thermoplastic composites) are emerging in industries as a replacement for metals due to their durability and lightweight composition. However, achieving high levels of both strength and toughness in thermoplastic composites is challenging, hindering their ability to be manufactured at fast rates.

Funded by the National Science Foundation’s (NSF) Faculty Early Career Development (CAREER) Award, Dr. Amir Asadi, assistant professor in the Department of Engineering Technology and Industrial Distribution at Texas A&M University, has developed a method using hybrid nanomaterials capable of creating high-performance thermoplastic composites with favorable mechanical properties within minutes.

Funded by the National Science Foundation’s (NSF) Faculty Early Career Development (CAREER) Award, Dr. Amir Asadi, assistant professor in the Department of Engineering Technology and Industrial Distribution at Texas A&M University, has developed a method using hybrid nanomaterials capable of creating high-performance thermoplastic composites with favorable mechanical properties within minutes.

Fiber-reinforced thermoplastics are replacing metals at high rates because of their inherent properties — they are light, strong, recyclable and malleable. They can be used in various applications including manufacturing, automobile and aerospace industries, because they are both cost-effective and sustainable.

“With the premise that a 10% reduction in vehicle weight leads to a 6%-8% increase in fuel efficiency and a 325-kilogram reduction in its annual carbon dioxide emission, this project provides a scalable solution to compete with the manufacturing of metal parts in automotive industries,” said Asadi. “In addition, this project addresses the need for reduced weight and cost of manufacturing in aerospace, economically justifying manufacturing small aerial vehicles for imaging, radars, surveillance and deliveries. It also accelerates certification of fast-rate manufactured composites for commercial aircraft.”

High-performance thermoplastic composites are usually semi-crystalline, containing both crystalline and amorphous regions. In polymers, crystals are the regions that the polymer chains are in a specific order, and amorphous regions are those with random structures.

However, thermoplastic makeup presents a paradox: it will be brittle if strength is improved by increasing the number of crystals, but if the brittleness is addressed by having more amorphous regions, the strength decreases significantly. A fast-rate manufacturing process would induce this paradox due to the quick heating and cooling process that does not allow enough time for crystals to form, thus making it difficult to produce strong thermoplastics.

“Achieving structures with properties that act against each other is challenging,” said Asadi. “However, these structures exist in nature. For example, an elephant trunk is strong enough to lift hundreds of pounds, is stiff in fights, but also soft, flexible and delicate enough to handle small vegetables. Simultaneously, it serves versatile functionalities such as communication, drinking and showering. The key for these incredible functions is the intricate microstructure of the trunk, which we can look to as an example of how we can achieve paradoxical properties in one structure.”

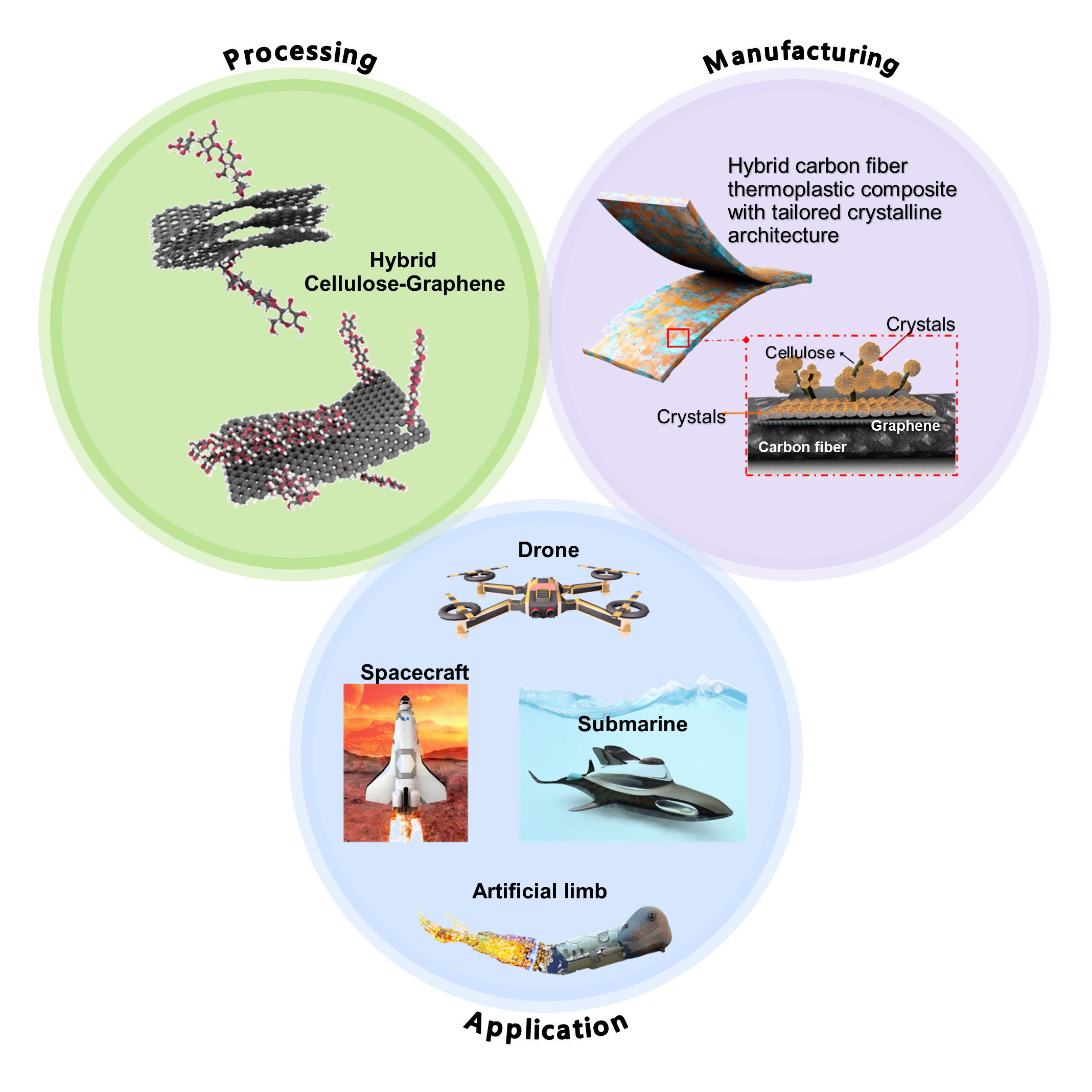

To meet this challenge, the researchers proposed engineering the crystalline-amorphous microstructure during manufacturing using hybrid nanomaterials. These nanomaterials can tailor the crystals into the desired architecture by controlling nucleation, growth, orientation and the size distribution of crystals. Developing the microstructure during production produces a thermoplastic composite that is both strong and fracture resistant.

Their new method could potentially produce fiber-reinforced thermoplastics at faster rates and lower costs. In addition, it could present a scalable solution capable of competing against metals in manufacturing.

“This project accelerates the manufacturing platforms that could benefit the United States economy and national security by equipping automotive, aerospace and marine industries with a fast-rate manufacturing technique,” said Asadi.

In the future, the researchers will look to provide physical evidence that their manufacturing process mirrors their molecular simulations. To accomplish this task, they are collaborating with the Air Force Research Laboratory to determine whether their research findings will be compatible with manufacturing processes.

The NSF CAREER program supports early-career faculty who show potential in the academic community and strive to advance the goals of their department or organization.

“With the premise that a 10% reduction in vehicle weight leads to a 6%-8% increase in fuel efficiency and a 325-kilogram reduction in its annual carbon dioxide emission, this project provides a scalable solution to compete with the manufacturing of metal parts in automotive industries,” said Asadi. “In addition, this project addresses the need for reduced weight and cost of manufacturing in aerospace, economically justifying manufacturing small aerial vehicles for imaging, radars, surveillance and deliveries. It also accelerates certification of fast-rate manufactured composites for commercial aircraft.”

High-performance thermoplastic composites are usually semi-crystalline, containing both crystalline and amorphous regions. In polymers, crystals are the regions that the polymer chains are in a specific order, and amorphous regions are those with random structures.

However, thermoplastic makeup presents a paradox: it will be brittle if strength is improved by increasing the number of crystals, but if the brittleness is addressed by having more amorphous regions, the strength decreases significantly. A fast-rate manufacturing process would induce this paradox due to the quick heating and cooling process that does not allow enough time for crystals to form, thus making it difficult to produce strong thermoplastics.

“Achieving structures with properties that act against each other is challenging,” said Asadi. “However, these structures exist in nature. For example, an elephant trunk is strong enough to lift hundreds of pounds, is stiff in fights, but also soft, flexible and delicate enough to handle small vegetables. Simultaneously, it serves versatile functionalities such as communication, drinking and showering. The key for these incredible functions is the intricate microstructure of the trunk, which we can look to as an example of how we can achieve paradoxical properties in one structure.”

To meet this challenge, the researchers proposed engineering the crystalline-amorphous microstructure during manufacturing using hybrid nanomaterials. These nanomaterials can tailor the crystals into the desired architecture by controlling nucleation, growth, orientation and the size distribution of crystals. Developing the microstructure during production produces a thermoplastic composite that is both strong and fracture resistant.

Their new method could potentially produce fiber-reinforced thermoplastics at faster rates and lower costs. In addition, it could present a scalable solution capable of competing against metals in manufacturing.

“This project accelerates the manufacturing platforms that could benefit the United States economy and national security by equipping automotive, aerospace and marine industries with a fast-rate manufacturing technique,” said Asadi.

In the future, the researchers will look to provide physical evidence that their manufacturing process mirrors their molecular simulations. To accomplish this task, they are collaborating with the Air Force Research Laboratory to determine whether their research findings will be compatible with manufacturing processes.

The NSF CAREER program supports early-career faculty who show potential in the academic community and strive to advance the goals of their department or organization.