For more than a decade, industry groups and task force reports have identified a growing crisis around the ability to attract, retain and modernize a competitive manufacturing workforce. Smart and advanced manufacturing technologies present a vital opportunity to invigorate and revitalize the American manufacturing base.

According to a study by Deloitte, the need for skilled manufacturing employees is a persistent problem expected to result in 2.1 million unfilled manufacturing jobs by 2030. This estimate may be conservative due to the ongoing mass exodus of manufacturing employees in what has come to be called the “Great Resignation.”

“In an industry with tiered supply chains that cover specialized material production, advanced digital manufacturing processes and more, the lack of suitably skilled workers is more than competitive liability; it’s a threat to national security,” said Dr. Darrell Wallace, deputy director and chief technology officer at the SecureAmerica Institute (SAI).

Numerous publications, including the Reagan Institute’s Renaissance Report and the Biden Administration’s executive order on supply chains, cite upskilling the workforce and injecting smart manufacturing technologies into the American manufacturing base as imperative to national security and economic prosperity.

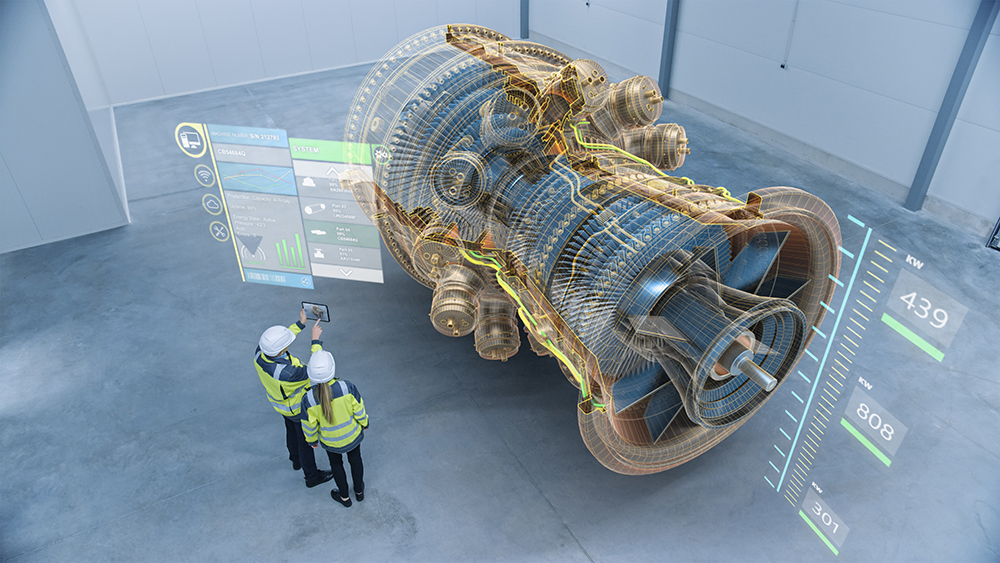

“Though we still have a long way to go, digital threads are rapidly weaving a tapestry across the entirety of the manufacturing enterprise,” Wallace said. “Tomorrow’s competitive manufacturers will be agile, digital and ‘smart’ in the newest sense of the word. Thriving in this new competitive landscape will require manufacturers to rethink long-established paradigms for technology, workforce and operating models.”

Small manufacturers, which comprise a large portion of the American manufacturing base, face many barriers when adopting smart manufacturing practices. Furthermore, as the industry embraces digital transformation, employers cannot overlook the need to fill highly skilled positions in traditional manufacturing roles like machining, welding and industrial maintenance.

“The need for a skilled workforce in manufacturing spans the breadth of traditional, advanced and emerging manufacturing processes,” Wallace said. “This is particularly relevant because Texas is the number-one producing state in the aerospace and defense manufacturing sectors.”

On May 9, 2022, SAI will convene members of the Texas Defense Aerospace Manufacturing Community to explore strategic challenges facing the future of defense and aerospace manufacturing in Texas.

“We are going to hear from leading aerospace and defense manufacturing companies that have already begun their digital journeys and are leading the way in fully integrating smart manufacturing capabilities into their factory,” said Chris Holshouser, SAI’s director of applied programs and strategic partnerships. “Events like this allow the industry to share in one another’s achievements and will hopefully set the entire community on a path for success.”

“We look forward to discussing challenges to the industry and converging our considerable consortium thought leadership to develop impactful plans focused on enhancing the long-term robustness and prosperity of manufacturing in Texas,” Wallace said. “Concurrently, these actions will contribute to the overall security and stability of the American industrial base.”

The Texas Manufacturing Renaissance

Join the SecureAmerica Institute and the Texas Defense Aerospace Manufacturing Community at the Texas Manufacturing Renaissance on May 9, 2022. Learn more about the event and register today.