The process of fabricating materials is complicated, time-consuming and costly. Too much of one material, or too little, can create problems with the product, forcing the design process to begin again. Advancements in the design process are needed to reduce the cost and time it takes to produce materials with targeted properties.

Funded by the National Science Foundation (NSF), researchers at Texas A&M University are using advanced computational and machine-learning techniques to create a framework capable of optimizing the process of developing materials, cutting time and costs.

“Our general focus is working on materials design by considering process-structure-property relationships to produce materials with targeted properties,” said Dr. Douglas Allaire, associate professor in the J. Mike Walker ’66 Department of Mechanical Engineering. “In our work, we demonstrate a microstructure sensitive design of alloys with a Bayesian optimization framework capable of exploiting multiple information sources.”

Bayesian optimization-based frameworks use prior knowledge as models to predict outcomes. In the past, researchers have used this framework in correlation with a single information source (simulation or experiment). If that method failed, the process starts again with the hopes of making the right adjustments based on this model.

The researchers have rejected this notion and instead believe that many information sources can be pulled using a Bayesian framework to develop a more complete picture of underlying processes. They have combined multiple information sources to create materials with targeted properties more efficiently by looking at data in its entirety rather than its parts.

“What we think, that is very different, is that you can have many different potential models or information sources,” said Dr. Raymundo Arróyave, a professor in the Department of Materials Science and Engineering. “There are many ways to understand/model the behavior of materials, either through experiments or simulations. Our idea is to combine all of these different models into a single, ‘fused’ model that combines the strengths of all the other models while reducing their individual weaknesses.”

Their research titled, “Efficiently exploiting process-structure-property relationships in material design by multi-information source fusion,” was recently published in Vol. 26 of the Acta Materialia journal.

“These model chains have historically not considered the breadth of available information sources,” said Allaire. “They consider single models along the chain from process, through structure, to property. As a result, they are not as efficient or accurate as they could be.”

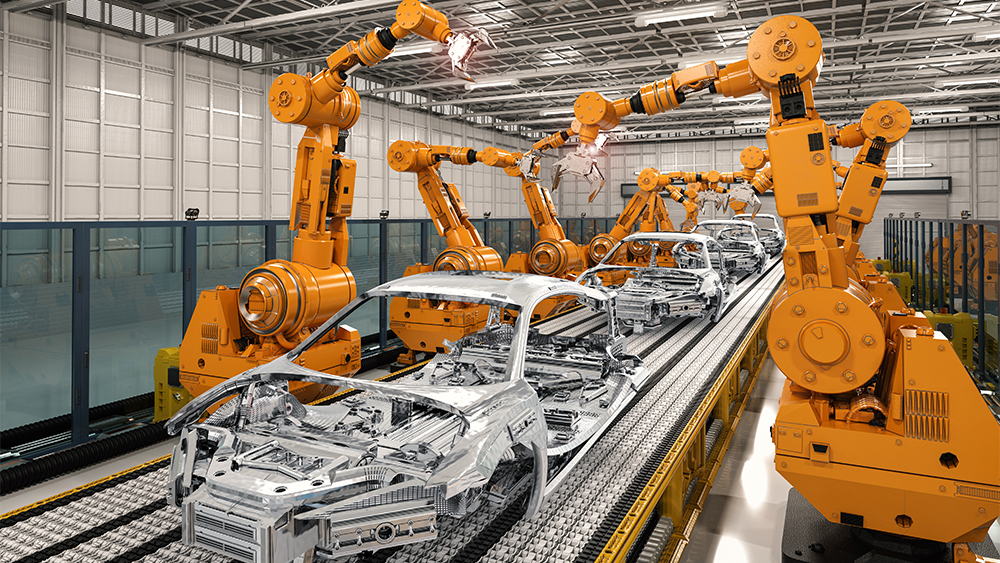

The researchers are currently testing this framework by developing dual-phase steels typically used on automobile frames. Dual-phase steels are made out of two phases with very different and complementary properties.

“There are two phases; the martensite phase makes this particular steel very strong,” said Arróyave. “The ferritic phase is softer and makes the steel more compliant and amenable to deformation. With only martensitic microstructures, these materials are strong, but they break easily. However, if you combine the strength of martensite with the ductility of ferrite, you can make steels that are very strong, can absorb energy during impact and that can be fabricated into complex shapes such as car frames.”

Using the method developed in this work, the goal is to develop a framework that more precisely and effectively predicts the needed composition and processing (recipe) for a specific design. In turn, this decreases the number of simulations and experiments required, drastically reducing costs.

“The knowledge that we gain about the material design process as a whole using our framework is much greater than the sum of all information extracted from individual models or experimental techniques,” said Dr. Ankit Srivastava, assistant professor for the materials science and engineering department. “The framework allows researchers to efficiently learn as they go, as it not only collects and fuses information from multiple models/experiments but it also tells them which information source i.e., a particular model or experiment provides them the best value for their money or time, which really enhances the decision-making process.”

In the future, they hope their framework is widely used when attempting tasks that involve integrated computational materials design.

“Our hope is that by presenting these model fusion-based Bayesian optimization capabilities, we will make the search process for new materials more efficient and accurate,” said Allaire. “We want any researcher to use the models that they have available to them without worrying as much about how to integrate the models into their own modeling chain because our Bayesian optimization framework handles that integration for them.”