The United States Army Research Laboratory is lending support to a Texas A&M University research project investigating potential improvement of ballistic performance of armor materials.

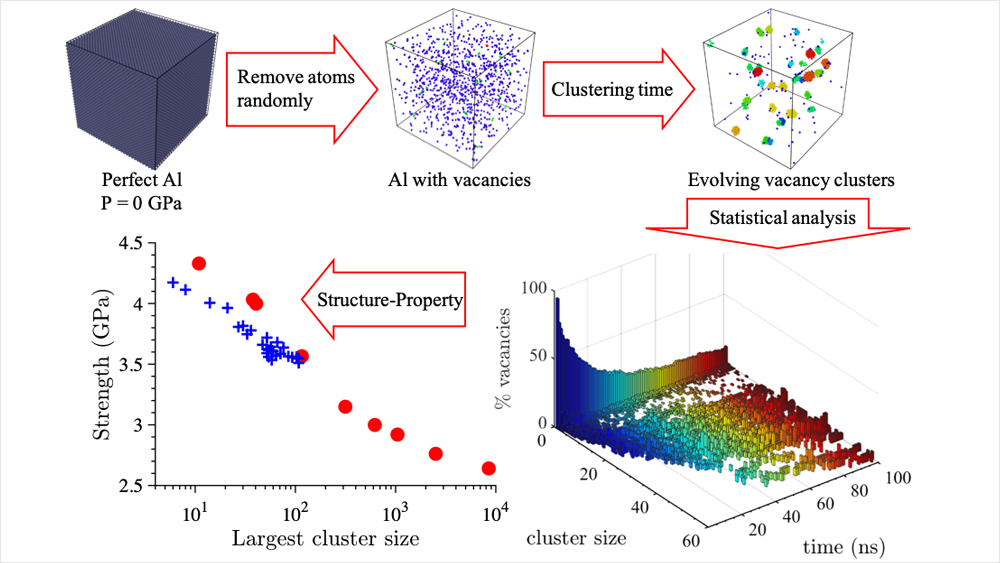

The project, led by Dr. Justin Wilkerson, assistant professor and James J. Cain ’51 Faculty Fellow II in the J. Mike Walker ’66 Department of Mechanical Engineering, focuses on identifying what damaging effects could be caused by particular flaws — known as vacancies — in the atomic structure of aluminum.

Wilkerson’s research paper on the topic, “Evolving structure-property relationships in metals with nonequilibrium concentrations of vacancies,” was recently featured on the cover of the Journal of Applied Physics. The paper was co-authored with Wilkerson’s former postdoctoral advisee Dr. Sara Adibi.

Although similar research has been conducted by Dr. Celia Reina and coworkers from the California Institute of Technology, Wilkerson’s study delves deeper into the subject by calculating the effect of changes due to vacancies over time on the material’s mechanical properties.

“Mechanical behavior of these materials could not be understood via the Lattice Kinetic Monte Carlo simulations alone, which was what had been done prior to this,” said Wilkerson. “To take the next step forward, we made use of supercomputing facilities to conduct a suite of large-scale molecular dynamics simulations.”

Atoms are arranged in a highly ordered pattern referred to as a crystal lattice, and if an atom is missing from a perfect lattice structure, this defect is called a vacancy. At high temperatures, the vacancies can come together, forming vacancy clusters.

Wilkerson said a large concentration of vacancies in a material may be generated under shock loading, which could impact ballistic performance metrics, including spall strength.

“The effect of vacancies on the mechanical behavior of materials on short timescales, such as microseconds, has remained largely unexplored,” said Wilkerson. “Even on such short timescales, we find that vacancies may also play a significant role in the high-temperature failure of metals subject to very high tensile pressures.”

A prospective idea from the findings is that it may be possible to use this knowledge to improve the ballistic performance of next-generation armors for the U.S. Army.

“Now that we better understand the importance of this mechanism to ballistic performance the next step is to develop material processing strategies that slow vacancy production rates in shocked materials,” said Wilkerson.

Bush Combat Development Complex

The Texas A&M University System’s George H. W. Bush Combat Development Complex (BCDC), under construction at the RELLIS Campus, is the result of a partnership with the Army Futures Command. The BCDC will bring together academic researchers, the military and the private sector for collaboration, demonstrations and high-tech testing of various national security initiatives.