Texas A&M University, through its unique Engineering Medicine (EnMed) partnership with Houston Methodist Hospital, is stepping up to help the health care system keep up with the demand for medical supplies brought on by the increasing number of confirmed and suspected COVID-19 cases.

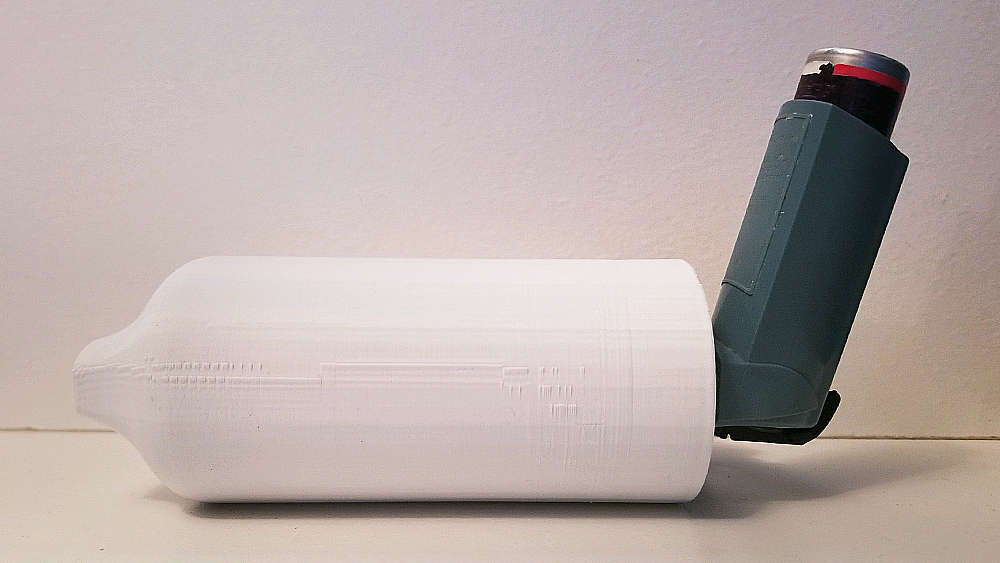

A team led by Dr. Michael R. Moreno has already delivered 200 3D-printed diffusers for metered dose inhalers (MDI) to the Houston hospital and stands ready to produce more if needed.

One of the most powerful aspects of the project is that it came from direct communication with doctors who, at the forefront of this crisis, are identifying emerging unanticipated needs.

“The spacer, or diffuser, that we created will allow the doctors to use metered dose inhalers to treat diagnosed and suspected COVID-19 patients who are not yet in need of ventilator therapy, without using nebulizers that may aerosolize the virus,” Moreno said. “And this is important because if this early stage intervention is effective, then it is possible that these patients may recover before reaching that critical point where ventilator therapy is required.”

Inhalers are the preferred method of delivery for bronchodilator drugs with confirmed and potential COVID-19 patients. The inhaler devices require precise timing of inhalation for proper delivery to the lungs, which is something Moreno said even experienced users, like himself, can find challenging.

With the help of a diffuser, patients are better able to get more of the medication into their lungs.If this early stage intervention is effective, then it is possible that these patients may recover before reaching that critical point where ventilator therapy is required.

“These spacers work like diffusers and allow the patient more time to draw the entire dose of medication into their lungs” Moreno said. “And when you're suffering from respiratory illness, this may be very important.”

Dan Metzen, system director of pharmacy services at Houston Methodist, said diffusers are currently in short supply due to the increased use of inhalers for both confirmed and suspected COVID-19 patients, leaving the hospital itself with a limited supply.

Metzen said nebulizers could also be used to administer the medication, but metered dose inhalers are preferred due to a concern that nebulizers used by patients with COVID-19 in the hospital could spread the virus.

Although the concept being utilized for the diffusers is not new, this is among the first times it has been locally 3D printed and delivered on this scale.

Anticipating that this shortage is likely not unique to Houston Methodist, Moreno and his team are making the stereolithography (STL) file for the 3D-printable design publicly available, at no cost.

Additionally, the team has designed an alternate, smaller 3D-printable device designed for areas that may be more resource limited. This device is essentially an inhaler interface that allows one to use a common plastic water bottle as the diffuser chamber.

EnMed Partnerships

Houston Methodist has a partnership with the Texas A&M College of Medicine and College of Engineering through the EnMed program, an integrated educational and research medical program with a focus on innovation. Dr. Roderic Pettigrew, executive dean of EnMed, said this rapid response by Moreno and his team to develop a use-inspired solution in the 3D printed diffuser serves as a perfect example of the program’s concept in action.

“Engineers are great at solving problems that benefit society, and the health care delivery system, right now, is very much in need of help with problem solving as we struggle with this pandemic and all of its associated challenges,” Pettigrew said. “EnMed has risen to the occasion right here in Houston to serve people in need. We’re working with our colleagues at Houston Methodist Hospital in order to devise practical solutions to real problems on the front lines of treating COVID-19 patients.”