With a touch of inspiration from MacGyver, Texas A&M University researchers have developed a way to make medical protective gear from readily available materials to construct desperately needed personal protection masks for medical personnel who have seen a depletion of resources as the number of COVID-19 cases increases.

Dr. John Criscione, a Texas A&M professor in the Department of Biomedical Engineering and a Johns Hopkins-educated medical doctor, said he and his colleagues are investigating a low-technology solution to a growing problem and have figured out a way to build medical masks with materials such as air-conditioning filters, sheer curtains, staples and stretchable cords.

“If the gap between supply and demand continues to worsen, and particularly our emergency medical colleagues are forced to use do-it-yourself masks, we want them to have technical guidance as they make their choices of materials and construction,” Criscione said. “We see this as our selfless service responsibility to the general public, as Aggies, and we are here to help.”

The project began after emergency room physicians asked Criscione to explore potential solutions, in case masks became unavailable.

The prototype never was intended to join the supply chain of approved personal protective equipment or personal protective equipment, Criscione said. Rather, the “Aggie masks” should be reserved for worst-case scenarios where overwhelmed hospitals “have no protective masks to use for life-saving procedures.”

Next steps

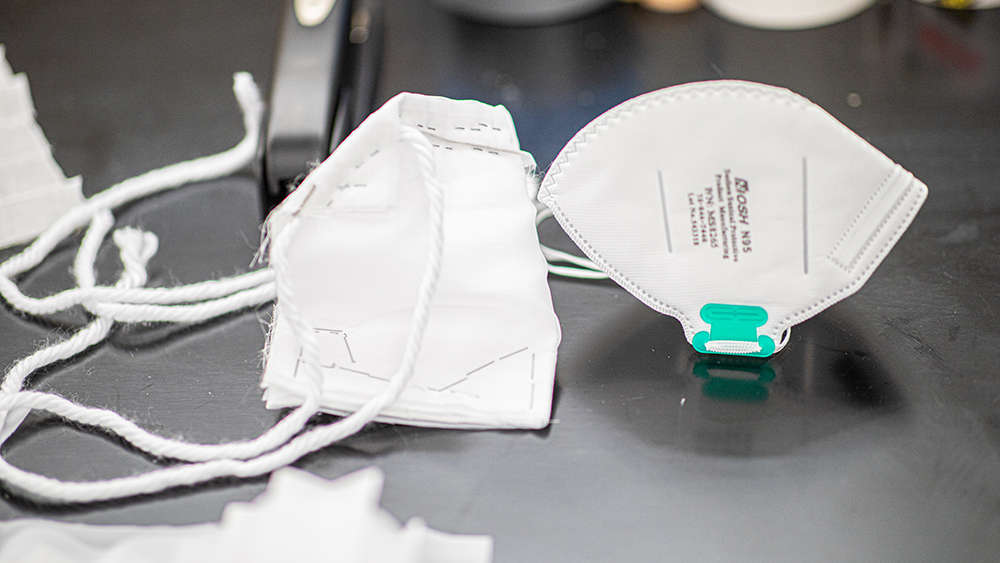

Criscione and his team will be quantitatively testing do-it-yourself masks in the coming days and will continue their efforts to create a mask that has features similar to the N95 respirator, which is capable of filtering 95% of airborne particles, including viruses. (Surgical masks cannot block as much.)

Another group at Texas A&M’s College of Engineering is working on options to produce similar personal protective masks using 3D printers.